In the dynamic landscape of industry and commerce and the integration of new technology is not merely an option but a necessity for businesses striving to remain competitive. The infusion of technology into production processes has brought about transformative changes and reshaping the way goods and services are manufactured, delivered, and consumed. This essay delves into the multifaceted impact of new technology on production, exploring its implications for efficiency and innovation, sustainability, & workforce dynamics.

The Evolution of Production Technology

The journey of production technology has traversed through distinct phases and each marked by significant advancements and paradigm shifts. From the mechanization of the Industrial Revolution to the automation & digitization of the modern era and technological progress has been instrumental in augmenting productivity & refining operational processes.

Mechanization and Industrial Revolution

Steam engines, mechanical looms, & early assembly lines revolutionized production in the 18th and 19th centuries.

Mass production became feasible and leading to economies of scale & lower per-unit costs.

Automation & Computerization

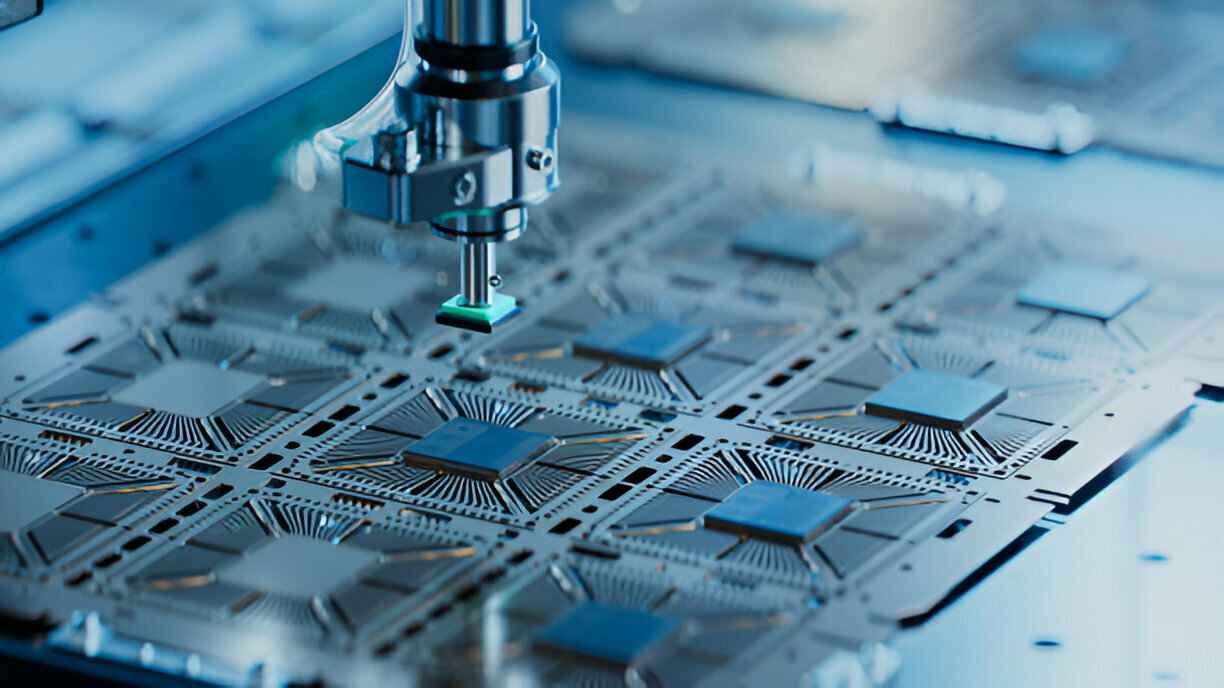

The mid-20th century witnessed the rise of automation with the advent of programmable logic controllers & computer-controlled machinery.

Robotics, CNC machines, & ERP systems streamlined workflows & enabled precise control over production variables.

Digitization and Industry 4.0

Industry 4.0, characterized by cyber-physical systems, IoT, AI, & big data analytics and represents the current era of production technology.

Smart factories leverage interconnected systems to optimize processes, enhance decision-making, & facilitate real-time monitoring.

Efficiency Enhancement through Technology

One of the most tangible benefits of integrating new technology into production is the enhancement of operational efficiency across various dimensions.

Process Optimization

Automation of repetitive tasks reduces human error and increases accuracy, & ensures consistency in output quality.

Advanced algorithms optimize production schedules and resource allocation, & inventory management, minimizing wastage and downtime.

Real-time Monitoring and Control

IoT-enabled sensors & devices provide real-time data on equipment performance and allowing proactive maintenance and troubleshooting.

Remote monitoring capabilities enable supervisors to oversee operations from anywhere and enhancing responsiveness & decision-making.

Predictive Maintenance

Machine learning algorithms analyze historical data to predict equipment failures before they occur, optimizing maintenance schedules & minimizing disruptions.

Predictive maintenance reduces unplanned downtime, extends asset lifespan, & lowers maintenance costs.

Innovation Catalyst: Driving Product Development & Customization

New technology acts as a catalyst for innovation and empowering businesses to create & deliver products that meet evolving customer preferences & market demands.

Rapid Prototyping and Iterative Design

3D printing technology facilitates rapid prototyping and enabling designers to quickly iterate & refine product designs based on customer feedback.

Iterative design accelerates the product development cycle and reduces time-to-market, & fosters agility in responding to market trends.

Customization and Personalization

Advanced manufacturing techniques such as additive manufacturing & CNC machining enable on-demand production of customized products.

Personalized products cater to niche markets & individual preferences and enhancing customer satisfaction and brand loyalty.

Collaborative Innovation Ecosystems

Digital platforms & collaborative tools facilitate cross-functional collaboration & knowledge sharing among stakeholders, fostering a culture of innovation.

Open innovation initiatives and partnerships with startups, & co-creation with customers unlock new ideas and drive continuous improvement.

Sustainability Imperative: Green Technologies and Circular Economy

The integration of sustainable practices & green technologies in production processes has emerged as a strategic imperative for businesses aiming to reduce environmental impact & align with societal expectations.

Energy Efficiency and Renewable Resources

Energy-efficient technologies such as LED lighting and smart HVAC systems, & energy management software minimize energy consumption & lower carbon emissions.

Integration of renewable energy sources like solar panels & wind turbines reduces reliance on fossil fuels & promotes sustainability.

Waste Reduction and Recycling

Circular economy principles emphasize waste reduction and reuse of materials, & recycling to minimize environmental footprint.

IoT-enabled sensors & data analytics optimize resource utilization, identify waste streams, & facilitate closed-loop systems.

Sustainable Supply Chains

Adoption of blockchain technology enhances transparency & traceability in supply chains, ensuring ethical sourcing, fair labor practices, & environmental compliance.

Supplier collaboration platforms enable businesses to partner with eco-friendly suppliers & promote sustainable practices throughout the value chain.

Workforce Dynamics: Reskilling, Collaboration, & Human-Machine Interaction

The integration of new technology reshapes the dynamics of the workforce and requiring upskilling, reskilling, & fostering collaboration between humans & machines.

Skills Transformation and Lifelong Learning

Automation and AI-driven tools augment human capabilities, leading to a shift in skill requirements towards data analytics, programming, and digital literacy.

Lifelong learning initiatives, training programs, and online platforms empower employees to adapt to technological changes and acquire new skills.

Human-Centric Design and Collaboration

Human-machine collaboration emphasizes ergonomic design and user-friendly interfaces, and intuitive workflows to enhance productivity and user experience.

Collaborative robots (cubits) work alongside humans and automating repetitive tasks while allowing employees to focus on complex, creative activities.

Ethical Considerations and Well-being

Ethical AI frameworks & guidelines ensure responsible use of technology, mitigate biases, & safeguard privacy and data security.

Work-life balance initiatives, wellness programs, & ergonomic work environments prioritize employee well-being and mental health amidst technological advancements.

Future Trends and Challenges

Looking ahead, several trends & challenges shape the trajectory of production technology & its impact on businesses & society.

AI and Cognitive Automation

Advancements in AI, machine learning, & natural language processing enable cognitive automation and transforming decision-making processes & predictive analytics.

Digital Twins & Virtual Simulation

Digital twins replicate physical assets digitally and enabling virtual simulations, predictive modeling, & scenario analysis for optimized performance & risk mitigation.

Cybersecurity and Data Privacy

The proliferation of interconnected systems & IoT devices underscores the importance of robust cybersecurity measures & data privacy regulations to protect sensitive information.

Skills Gap and Talent Acquisition

Bridging the skills gap through continuous learning and talent development, & strategic workforce planning remains a priority for organizations navigating technological disruptions.

Conclusion

The transformative impact of new technology on production is evident across all facets of business operations and from enhancing efficiency & fostering innovation to promoting sustainability & reshaping workforce dynamics. Embracing technological advancements requires a strategic vision and continuous learning mindset, and collaborative approach to harness the full potential of digital transformation. As businesses navigate the evolving landscape of production technology, adaptation, agility, & responsible stewardship of technology remain critical for sustainable growth & competitiveness in the digital age.