The assembly line is one of the most significant technological improvement in modern industrial history, revolutionizing manufacturing processes across various industries. Introduced by Henry Ford in 1913, the assembly line transformed the way goods were produced, leading to increased efficiency, lower costs, and higher productivity. In this comprehensive guide, we will explore the impact of the assembly line on technology, economics, society, and the environment, highlighting its key benefits and challenges.

1. Introduction to the Assembly Line

The assembly line is a manufacturing process where products are assembled sequentially as they move along a conveyor belt or a series of workstations. This method replaced the traditional craft production system, where skilled craftsmen would create each product individually from start to finish. The assembly line introduced standardized parts, specialized tasks, and a continuous flow of production, resulting in mass production capabilities.

2. Historical Context and Development

The concept of the assembly line has its roots in early manufacturing practices, such as the Venetian Arsenal in the 16th century, where ships were constructed using a systematic approach. However, it was Henry Ford who popularized the assembly line with the mass production of automobiles, particularly the Ford Model T.

3. Impact on Manufacturing Efficiency

One of the primary benefits of the assembly line is its ability to significantly increase manufacturing efficiency. By breaking down the production process into smaller, specialized tasks, workers can focus on specific areas of expertise, leading to faster production times and reduced labor costs.

4. Standardization and Quality Control

The assembly line also promotes standardization, ensuring that each product meets the same quality standards. With standardized parts and procedures, manufacturers can identify and address issues more effectively, leading to improved overall product quality.

5. Economic Implications

From an economic perspective, the assembly line has had a profound impact on various aspects of the economy. It has facilitated mass production, leading to lower prices for consumers and increased market competitiveness. Additionally, the assembly line has created job opportunities, although it has also led to concerns about job displacement and the need for worker retraining.

6. Social and Cultural Effects

The assembly line has not only transformed manufacturing but also had broader social and cultural effects. It has influenced consumer behavior by making products more affordable and accessible to a wider audience. However, it has also raised questions about the nature of work and the role of automation in society.

7. Environmental Considerations

While the assembly line has improved efficiency and productivity, it has also raised environmental concerns. Mass production can lead to increased waste and resource consumption, highlighting the need for sustainable manufacturing practices and eco-friendly technologies.

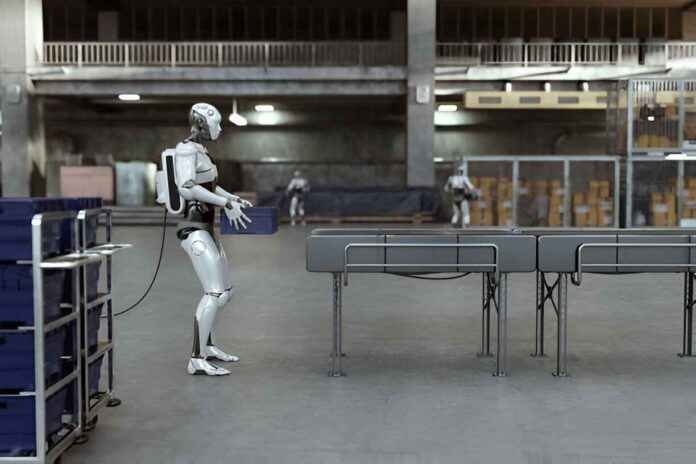

8. Technological Improvement

The implementation of assembly lines has driven technological innovations in manufacturing equipment and processes. From automated robotics to advanced production scheduling software, technology continues to play a crucial role in optimizing assembly line operations.

9. Challenges and Future Trends

Despite its many benefits, the assembly line also faces challenges such as workforce automation, supply chain disruptions, and the need for continuous innovation. Future trends in assembly line technology may include greater use of artificial intelligence, augmented reality, and sustainable manufacturing practices.

Conclusion Technological Improvement

In conclusion, the assembly line has been a transformative technological improvement with far-reaching implications for manufacturing, economics, society, and the environment. Its efficiency, standardization, and economic impact have shaped the modern industrial landscape, driving innovation and progress across various industries. However, ongoing challenges and evolving technologies will continue to shape the future of assembly line manufacturing, emphasizing the importance of adaptability and sustainability in the manufacturing sector.